GSL 8 line with two flow-pack units allows to reach higher capacity, when natural chocolate is used for coating and up to 16 000 cheeses per hour capacity for classic bars.

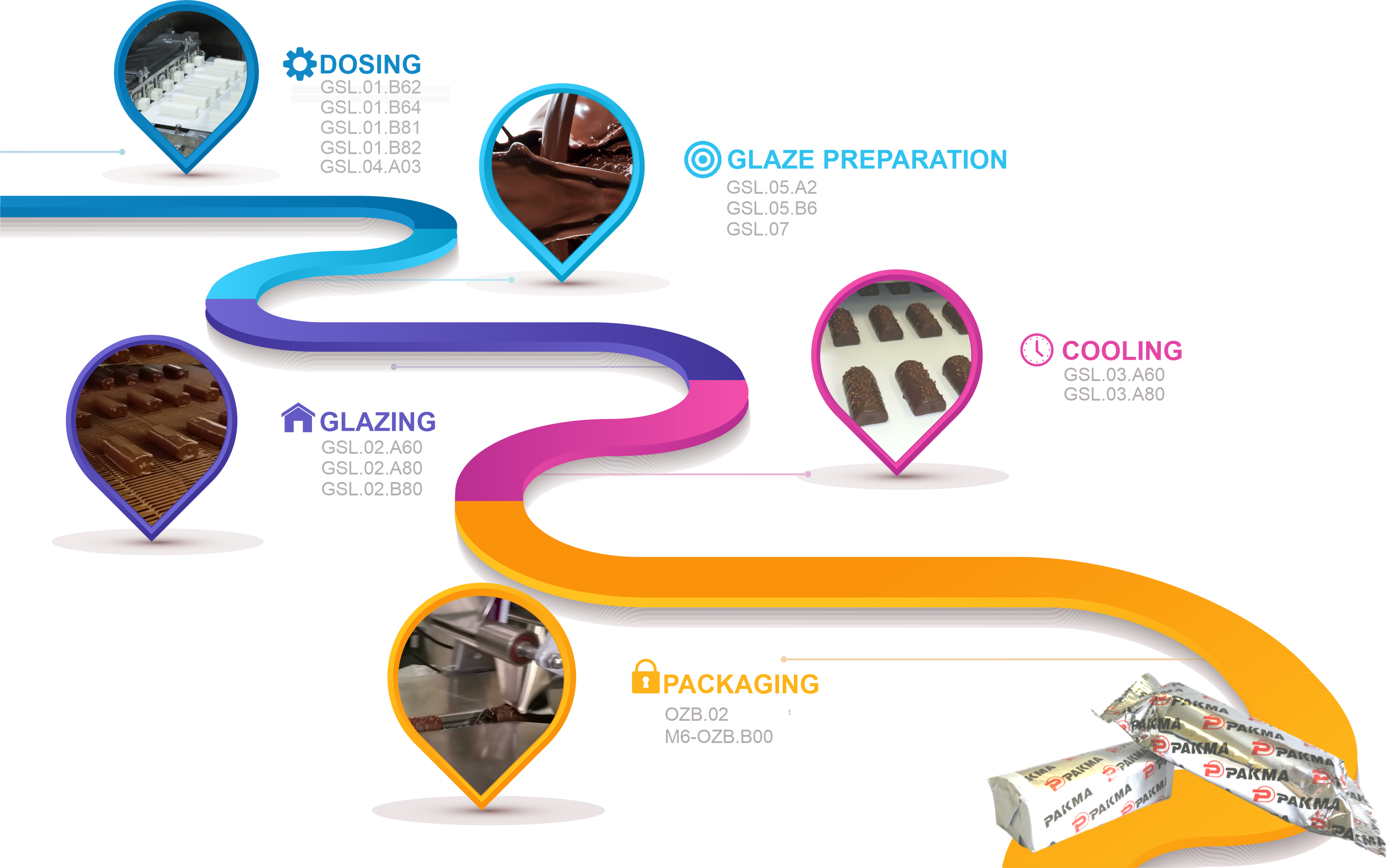

Technological equipment set GSL comes in different basic modifications of the line, allowing to produce a wide range of glazed curd cheeses (classic – vanilla taste, with filling, sprinkled with dressing and looking like small cake, when curd mass is dosed on a waffle or cookie). The line is equipped with all necessary equipment for dosing, enrobing, cooling, transporting, packaging: flow-pack type with laminated polypropylene film (with metallisation and interlayer printing) and wrapping type with laminated aluminum foil.

Different and unique GSL line modifications are available:

Short introduction video to see it yourself!

Short introduction video to see it yourself!