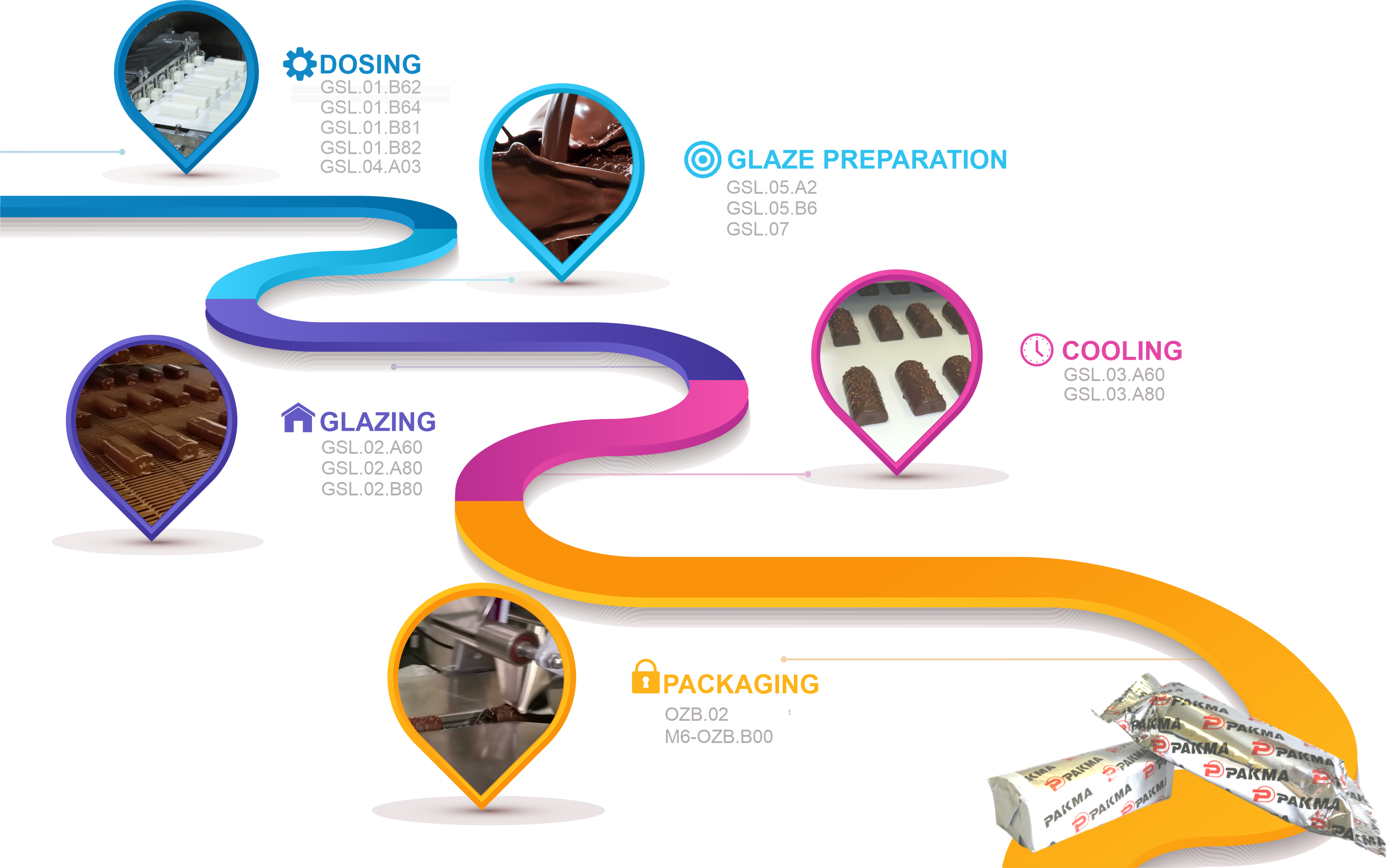

to 3 M6-OZB wrapping units and

2 OZB.02 flow-pack units

GSL.00.600

to 3 M6-OZB wrapping units and

2 OZB.02 flow-pack units

• capacity – up to 12 000 flow-pack packed bars per hour or

• capacity – up to 12 000 wrapped bars per hour or

• capacity – up to 8 000 flow-pack packed bars per hour and up to 8 000 wrapped bars per hour;

• primary product transportation to M6-OZB equipment and/or to OZB.02 flow-pack type packing equipment with integrated inkjet date printers;

• secondary product transportation to M6-OZB wrapping equipment or to OZB.02 flow-pack type packing equipment with integrated inkjet date printers;

• transportation system to M6-OZB wrapping equipment unit.

The distributing system performs the following operations: