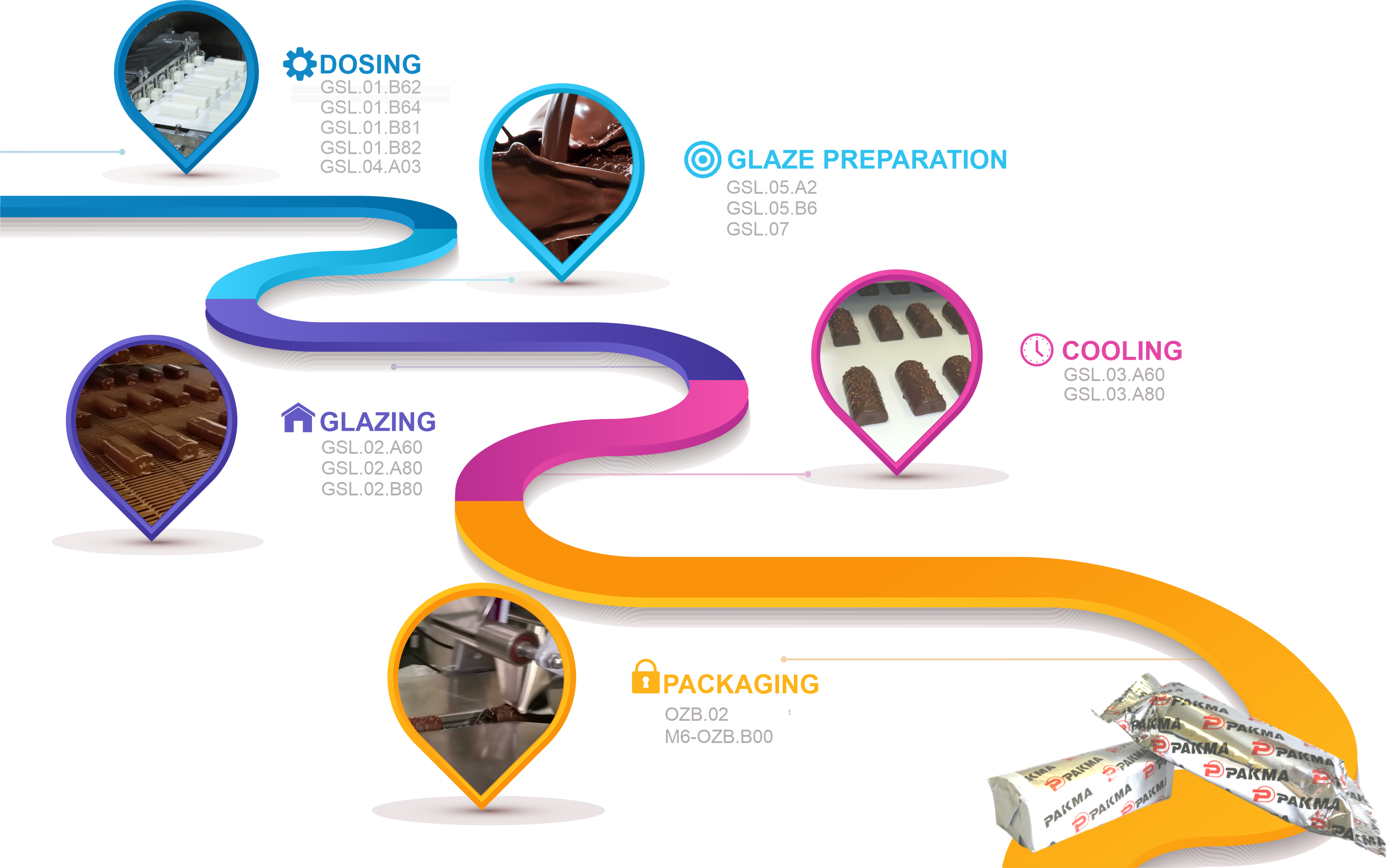

Distribution system

to M6-OZB wrapping and 2 pcs. OZB.02

flow-pack units

GSL.09.A00

Distribution system

to M6-OZB wrapping and 2 pcs. OZB.02

flow-pack units

Capacity:

Operating principle:

Capacity:

Operating principle:

The distributing system performs the following operations: